Javier Zambrano Cardozo

Sustainable Procurement: Best Practices and Benefits

In an era where sustainability is no longer a buzzword but a guiding principle, the concept of sustainable procurement has taken center stage. Today, we embark on a journey to explore the world of sustainable procurement, shedding light on its best practices and the array of benefits it brings to both businesses and the broader society.

Understanding Sustainable Procurement

Sustainable procurement, in essence, represents a commitment by organizations to source goods and services in a manner that considers economic, environmental, and social factors. It's more than just a box to tick; it's a strategic choice with far-reaching implications. Sustainable procurement is about making conscious choices that resonate with the values of responsible business practices.

We live in a world where consumers and stakeholders alike demand accountability and responsibility from businesses. As such, sustainable procurement is not merely an option but a strategic necessity that fosters long-term resilience.

Benefits of Sustainable Procurement

The benefits of embracing sustainable procurement practices are manifold. It's a win-win scenario for organizations, the environment, and society at large.

Financial Benefits: Sustainable procurement can lead to significant cost savings. By optimizing processes, reducing waste, and fostering efficiency, organizations can achieve tangible financial gains.

Environmental Benefits: Embracing sustainable procurement means reducing your environmental footprint. This translates to lower emissions, reduced waste, and conservation of natural resources. When businesses make sustainable choices, the planet wins.

Social Benefits: Sustainable procurement also extends its positive impact to society. Ethical sourcing practices ensure that products are made under fair labor conditions, supporting livelihoods and safeguarding human rights.

Best Practices in Sustainable Procurement

Implementing sustainable procurement practices requires careful planning and strategic thinking. Let's delve into some best practices:

Supplier Evaluation: Select suppliers not solely based on cost but also on their commitment to sustainability. Assess their environmental and social responsibility records.

Ethical Sourcing: Choose suppliers that uphold ethical practices in labor, sourcing, and production.

Sustainability Criteria: Integrate sustainability criteria into your procurement decisions. Ask questions like: How does this product impact the environment? What is its social footprint?

Collaboration: Work closely with suppliers and stakeholders to align objectives and foster a shared commitment to sustainability.

Challenges and Obstacles

While the benefits of sustainable procurement are undeniable, challenges can arise along the way. Supply chain complexity, resistance to change, and concerns about increased costs are among the common hurdles. However, organizations that persevere and invest in the right strategies can overcome these challenges and reap the rewards.

Measuring and Reporting Sustainability

Measuring and reporting sustainability metrics are crucial steps in the sustainable procurement journey. Utilize sustainability assessment tools and reporting frameworks like the Global Reporting Initiative (GRI) or ISO 20400 to gauge your progress. Transparency in reporting builds trust with stakeholders and showcases your commitment to sustainable practices.

Case Studies

To put theory into practice, let's explore real-world case studies of organizations that have successfully integrated sustainable procurement into their operations. These stories illuminate the concrete strategies and outcomes achieved by these trailblazing companies.

Future Trends in Sustainable Procurement

As the world evolves, so does sustainable procurement. Keep an eye on emerging trends and innovations in this space. Consider the evolving regulatory landscape, changing consumer expectations, and the potential impact of new technologies on sustainable procurement practices.

Conclusion

In closing, sustainable procurement isn't a mere buzzword; it's a dynamic force driving positive change in the business world. By adopting sustainable procurement practices, organizations not only contribute to a healthier planet but also ensure long-term profitability and resilience. It's an investment in a brighter future for businesses, communities, and the environment.

So, as you navigate the complex world of procurement, remember that sustainability isn't just a choice; it's the future.

References

- Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: Moving toward new theory. International Journal of Physical Distribution & Logistics Management, 38(5), 360-387.

- Waddock, S. (2015). Toward a paradigm of sustainability: A dialogue with David Cooperrider. Organization & Environment, 28(1), 54-67.

- ISO 20400:2017. Sustainable Procurement - Guidance.

- Global Reporting Initiative (GRI). Sustainability Reporting Standards.

PROJECT MANAGEMENT, PROCUREMENT, AND PROJECT PROCUREMENT MANAGEMENT

PROJECT

According with the Project Management Body of Knowledge guide (PMBOK®), fourth edition, a Project is a temporary endeavor undertaken to create a unique product, service, or result. The temporary nature of projects indicates a definite beginning and end. The end is reached when the project’s objectives have been achieved or when the project is terminated because its objectives will not or cannot be met, or when the need for the project no longer exists.

PROJECT MANAGEMENT

Project Management is the application of knowledge, skills, tools, and techniques to project activities to meet the project requirements. Project Management is achieved through the proper application and integration of the 42 logically grouped project management processes comprising the 5 Process Groups which are: Initiating, Planning, Executing, Monitoring and Controlling, and Closing. Effective project management requires planning, communication, and task management. But, do you know all the project management knowledge areas?. They are listed as follows:

- Project Integration Management

- Project Scope Management

- Time Management

- Cost Management

- Quality Management

- Human Resources Management

- Communications Management

- Risk Management

- Procurement Management

- Stakeholders Management.

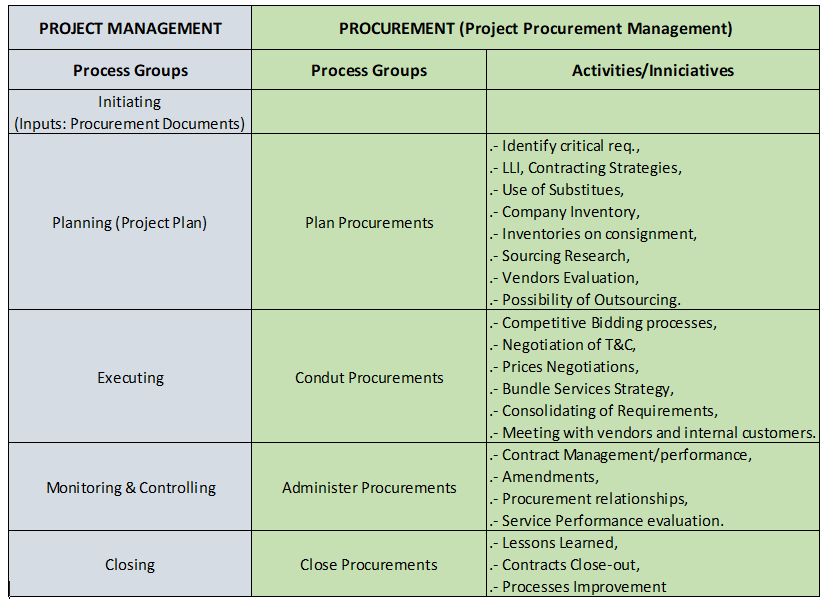

PROJECT PROCUREMENT MANAGEMENT

Project Procurement Management is one of the Project Management Knowledge Areas and includes the process necessary to purchase or acquire products, services, or results needed from outside the project team to perform the work. Project Procurement Management includes the contract management and change control processes required to develop and administer contracts or purchase orders issued by authorized project team members.

The Project Procurement Management processes include:

- Plan Procurements: The process of documenting project purchasing decisions, specifying the approach, and identifying potential sellers (Note of the Author: Annual Procurement or Contracting Plan).

- Conduct Procurements: The process of obtaining seller responses, selecting a seller, and awarding a contract.

- Administer Procurements: The process of managing procurement relationships, monitoring contract performance, and making changes and corrections as needed (Note of the Author: Contract Management).

- Close Procurements: The process of completing each project procurement (Note of the Author: Procurement and Contract Close-Out).

See below for a comparison between the philosophy of Project Management (process groups) and Procurement. Awesome, there are many coincidences. So, Procurement can be approached as Project Management.

Statistical Process Control and Control Charts in Six Sigma

SAP Ariba Supply Chain Collaboration Overview

Project Management Foundations - Procurement

Six Sigma Strategic Planning and Deployment

The 7 Steps of a Strategic Procurement Process

The procurement process can be complicated one. Strategic procurement is an organization-wide process. It requires input from all departments and functional areas for an organization. Organizations should set up a strategic procurement team. This team sets the overall direction for procurement, aligned with the business strategy. The team will then use the data from the strategic procurement process to develop and implement a strategic procurement plan.

Here are the 7 steps that lead to a successful procurement process.

Step 1: Conduct an internal needs analysis

To begin, you’ll need to benchmark current performance and then identify needs and targets before developing a procurement strategy. This involves the collection of several different types of data. The purpose for collecting initial data is to benchmark current performance, resources used, costs for all the departments/functions in the organization, and current growth projections.

Step 2: Conduct an assessment of the supplier’s market

In this step, the strategic procurement team identifies potential countries that are feasible sources of the required raw materials, components, finished goods or services. If there are specific requirements, it may limit the number of countries that are suitable. For instance, if one of the raw materials used by the organization can only be found in one country, then options are much narrower. For manufactured products, there will be a much wider range of potential countries from which to select. Services may be limited by the technological requirements of the organization.

Step 3: Collect supplier information

It is important for a company to select suppliers carefully. A supplier’s inability to meet selection criteria can result in significant losses for the organization. The business reputation and performance of the supplier must be evaluated, and financial statements, credit reports, and references must be checked carefully. If possible, the organization should arrange to inspect the supplier’s site and talk to other customers about their experiences with the supplier. The use of agents, who are familiar with the markets and stakeholders, can also be beneficial to this process. Organizations may select more than one supplier to avoid potential supply disruptions as well as create a competitive environment. This strategy is also effective for large multinational organizations and allows for centralized control, but more regional delivery.

Step 4: Develop a sourcing/outsourcing strategy

Based on the information gathered in the first three steps, an organization can develop a sourcing/outsourcing strategy. The following are examples of sourcing strategies: Direct purchase: Sending a Request for Proposal (RFP) or a Request for Quote (RFQ) to select suppliers. Acquisition: Purchasing from a desirable supplier. Strategic partnership: Entering into an agreement with a selected supplier. Determining the right strategy for you will depend on the competitiveness of the supplier marketplace and the sourcing/outsourcing organization’s risk tolerance, overall business strategy and motivation for outsourcing.

Step 5: Implement the sourcing strategy

Sourcing strategies that involve acquisition or strategic partnerships are major undertakings. In these cases, suppliers are likely to have the following characteristics: Involvement in activities core to the buyer, e.g. supply limited raw material for core product, access to highly confidential proprietary knowledge One of a limited number of available suppliers with specific equipment/ technology and skilled labour pool Part of the broader business strategy For a direct purchase, organizations may begin with an Expression of Interest (EOI), prepare an RFP or RFQ, and solicit bids from identified potential suppliers as part of a competitive bidding process. The RFP should include: detailed material product or service specifications delivery and service requirements evaluation criteria pricing structure; and financial terms.

Step 6: Negotiate with suppliers and select the winning bid

The strategic procurement team must evaluate responses from suppliers and apply its evaluation criteria. Bidding suppliers might request additional information in order to make the most realistic bid, and the organization should supply this information to all bidders and enable them to respond to the new information before making a final decision. The strategic procurement team will then evaluate the received proposals, quotes, or bids, and use the selection criteria and a process to either shortlist bidders to provide more detailed proposals (if reviewing EOIs) or select a first and second successful bidder (if reviewing RFPs or RFQs). After the evaluation process is complete, the strategic procurement team will enter contract negotiations with the first selected bidder.

Step 7: Implement a transition plan or contractual supply chain improvements

Winning suppliers should be invited to participate in implementing improvements. A communication plan must be developed and a system for measuring and evaluating performance will need to be devised using measurable Key Performance Indicators (KPIs).

Original article: http://www.tradeready.ca/2017/fittskills-refresher/7-steps-of-a-strategic-procurement-process/

Supply Chain Risks & the Failure to Plan for the Unexpected

'Supply Chain Risks & the Failure to Plan for the Unexpected'

Dear Fellow APICS Houston Members,

Recent years have seen a substantial increase in digital transformations and artificial intelligence (AI). As supply chain capabilities evolve with emerging technologies, companies operate as integrated end-to-end business model – as a result, the game to manage risk has changed, from managing supplier risks and analytics, to preparing for system failures and supply chain security.

2020 will be the year to test the resilience of your supply chain. Have you been proactively assessing your supply chain risks? Have you reviewed your supply chain risk management (SCRM) plan? Your plan should assist developing capabilities to prevent disruptions and minimize the impact of disruptions through your readiness assessment, quick response, and recovery plan.

Epidemics/Coronavirus, Chinese New Year (CNY) - have you been impacted?

TPM20 - the trans-Pacific and global container shipping, the largest container shipping event, was canceled 24 hours before it started in Long Beach, CA due to COVID-19. Blank sailings have been incorporated into the schedules, as of March 1st, the volume loss due to blank sailings was at 1.9M TEU; at a rough average freight rate of $1,000 per TEU, this equates to revenue loss of $1.9B for the carriers as reported in Seatrade Maritime Times. Factories in China are still struggling to get back to normal production levels. Multinational companies have warned that they will fall short of revenue goals for H2 and are putting at risk annual financial results due to stall production in China.

I often hear comments from people working outside the Supply Chain arena saying “Chinese New Year” (CNY) is only 2 weeks – so why does Supply Chain make a big deal of this and start planning in October? These comments lack the full understanding of the end-to-end impact in the entire global supply chain as well as their risks. After factoring in all variables, the actual impact is 6-8 weeks’ time to reach same production levels prior to CNY. I admit, the 2020 resilience test is an unusual due to the stall production due to the epidemic outbreak right after CNY.

Could you have done anything different in your strategic sourcing? We don’t know when natural disasters, global warming, epidemics, trade agreements, and other disruptions are going to happen, but we do know they will happen again. The failure to adequately evaluate, prevent, and minimize potential supply chain risks can ruin a business. The risks are serious, from losing market share to business extinction because of failing to predict the risks of changing conditions in your supply chain.

Additionally, as we enter into the next decade with Industry 4.0 driving transformations in manufacturing, supply chain, distribution, and retail. This digital disruption requires companies to rethink the way they design their supply chain and deliver products/services. As we develop new business models, we should also assess our supply chain readiness for potential disruptions and develop your SCRM plan.

In closing, I like to highlight some key events and accomplishments:

- 2020 Technology Innovation Summit – March 25th @ Hilton Galleria

- In response to the rise of AI, our 2nd Technology Innovation Summit will focus on AI. Industry experts will discuss the milestones, trends, and challenges.

- Showcasing: meal delivering robots and traceability/transparency winery project.

- ASCM Deloitte Supply Chain Case Competition: The UoH Team won the District Round and moved to the final at ASCM International Conference in New Orleans in September.

- New Website: APICS Houston launched a new upgraded website on March 1, 2020.

I wish all a very happy spring break with your family and friends. I hope to see you all on March 25th at the 2020 Technology Innovation Summit. Go to Apics-hourston.org for registrations.

Please remember that our volunteers are making a difference in our community. I’m sure you’ll also enjoy these opportunities to serve, grow, and to make others feel better because of your service. If you are interested please send me an email to This email address is being protected from spambots. You need JavaScript enabled to view it.. Space is limited.

Best,

Dave Cabello

President – APICS Houston

Pareto Principle and Bundle Services Discount Strategy

Pareto Principle or Pareto Law is a useful tool to help you prioritize and manage the work in your business, among other applications and disciplines. The pareto principle has become a popular business maxim that is based on the prediction that 80% of effects come from 20% of causes. It has been used to describe everything from economics to projects. Also, this law is of a great support when identifying the services or goods to be considered in the operationalization of the “Bundle Services Discount Strategy”, a marketing tactic that involves offering two or more goods or services as a package deal (consolidation of requirements) for a discounted price, which is negotiated and mutually agreed between Buyer(s) and Seller(s).

In 1906, Italian economist Vilfredo Pareto, an Italian engineer, sociologist, economist, political scientist, and philosopher who made several important contributions to economics, particularly in the study of income distribution and in the analysis of individuals' choices, created a mathematical formula to describe the unequal distribution of wealth in his country. Pareto observed that 20% of the people owned 80% of the nation's wealth. In the following years, this rule was applied with uncanny accuracy to many situations and be useful in many disciplines, including the study of business productivity. Other examples related with the application of this tool are mentioned as follows[1]:

- Project Management: 20% of the work consumes 80% of the time and resources. 80% of value is achieved with the first 20% of effort.

- Program Management: 80% of problems originate with 20% of projects.

- Management: 80% of work is completed by 20% of your team.

- Technology: 80% of customers only use 20% of software features.

- Sales & Marketing: 80% of sales come from 20% of your clients. 80% of sales come from 20% of your products. 80% of sales come from 20% of your salespeople. 80% of your complaints come from 20% of your customers.

- Wealth Management: 80% of wealth is owned by 20% of people.

As a result of my professional experience working with a major Oil Operator in the Gulf of Mexico (“GoM”), I have had the opportunity to apply this Pareto Principle with the purpose to contribute on adding value to business operations by implementing of the effective negotiation strategy named “Bundle Service Discounts” with major drilling and logistics contractors for drilling, well, logistics and downstream service contracts. Utilizing this tool, I was able to identify thirty-two (32) major contractors, related with approximately 20% of the total agreements signed between Oil Operator and Contractors in the GoM with an associated contracts value representing 80% of the total contract amount executed between the parties.

Figure # 1 – 80% Contracts Value

Based on the above evaluations, negotiation rounds were conducted with the 32 identified major contractors, resulting in approximately US$20.9 million cost savings on contract price discounts. This achievement was recognized by the Oil Operator given that this Key Performance Indicator (KPI) achieved a 33% margin above the contract original discount target established by the Company, for Cost Optimization initiatives.

These effective negotiation strategies were also applied as a proactive and preventive initiative which resulted in the execution of Master Services Agreements (MSAs) with major U.S Contractors operating in the GoM for attending to Emergency Scenarios that could arise as a result of oil spill events and in accordance with Oil Spill Response Plan (OSRP) approved by the U.S. Bureau of Safety and Environmental Enforcement (BSEE), as per the Code of Federal Regulations, Title 30 – Mineral Resources – Part 254 “Oil Spill Response Requirements For Facilities Located Seaward of the Coast Line” (30 CFR Part 254). This challenging MSA project took into consideration the provision of 28 category of services associated to emergency situations (i.e. Emergency Medical Services - SAR/MEDEVAC, Helicopter transportation services for search and rescue, Support vessels, Firefighting boats, Drilling Contractors, Marine Contractors, Oil Spill Equipment, Airplanes, Dispersant application, Land Transportation, Waste Disposal, etc.) and the implementation of the lessons learned from the “Macondo” well accident (blowout) occurred in April 2010 on the Macondo prospect in the GoM.

One of the most relevant executed agreements (as per BSEE requirement), was the MSA signed between Oil Operator and a Consortium of Deepwater operators and non-operators committed to building the safest, and fastest Deepwater containment response system, including to access to well capping & containment equipment and services in the event of an uncontrolled flow of hydrocarbons in the GoM. As a result of this negotiated agreement, Oil Operator obtained (i) cost saving of approximately 50% when compared with the average marketplace rates, (ii) reductions in the operational costs per well and (iii) accessing to capping, containment and technical support from peer companies in the GoM.

[1] https://management.simplicable.com/management/new/examples-of-the-pareto-principle

My New Book

Dear Friends, now available on Amazon the VOLUME II of my book “Logistics Planning for Exploratory Well Projects in Remote Locations”, in two presentations: e-Book and Paperback.

After covering the first portion of this study, the first book titled “Logistics Planning for Exploratory Well Projects in Remote Locations, Volume I” which provides a comprehensive description of the conceptual basis for project management based on the PMBOK® Guide together with the information gathered by this research, the experiences by offshore oil & gas drilling companies and my personal professional e xperience, I now continue my project planning path by carrying on with Volume II viewing and applied an methodological approach to project management planning exclusively focused on the logistics required to deploy offshore drilling operations.

xperience, I now continue my project planning path by carrying on with Volume II viewing and applied an methodological approach to project management planning exclusively focused on the logistics required to deploy offshore drilling operations.

Now, I take all the project planning processes explained in detail in Volume I, and apply them to my study case, a simulation where I plan the logistics for an exploratory well project to be developed in a remote location.

If the reader is unfamiliar with project planning, a good parting point would be Volume I. However, if the reader is familiar with project planning processes, especially those based on PMBOK® philosophy, this point on would be a good starting point.

The reader is advised that PMBOK® and all references in the book are registered trademarks of the Project Management institute, Inc. PMBOK® guide processes have been used as reference and have been paraphrased, nevertheless, the PMBOK® Guide shall remain as the certain and definite body of knowledge. All references to the Project Management Institute and PMBOK® guide are done with educational purposes and no copyright.

Here the link:

Paperback and eBook versions: