The need for petroleum-based energy self-sufficiency has led nations to continuously seek new discoveries and maximize hydrocarbon extraction, either on the basis of achieving optimization and technological improvements in exploration and production processes, or by expanding exploratory horizons to search for hydrocarbons.

The 1950s marked an increase in exploratory activity and the intensification of sea expeditions, made possible by the emergence of new exploratory techniques. Over the years, a wide variety of marine structures has been developed, including vessels and platforms equipped for drilling. Currently, some of these drilling units operate in water depths greater than 10,000 feet.

New frontiers in deep-water oil exploration have imposed a series of challenges for the oil industry. One of these challenges is to provide highly efficient services for offshore platforms and drilling rigs in order to keep them operating 24 hours a day, seven days a week (24/7) in the most cost-effective manner.

Thousands of people have to be transported to the platforms as well as food supplies, maintenance parts, equipment, bulk cargo, fuel, water and other fluids. Support boats and helicopters are used to meet such mobilization needs. Drilling operations are expensive and require continuous allocation of equipment, in some situations this allocation could be difficult to predict.

Complex onshore logistics, comprising a network of reliable suppliers, support base, seaports, airports, heliports, etc., is needed to support offshore operations in remote areas. Currently, most offshore logistics activities are still carried out in a traditional way, breaking or segmenting the logistics chain into "silos" with little synchronization throughout the process.

In order to successfully meet required logistical needs for offshore exploratory well, I highly recommend to conceive each well as an autonomous PROJECT to establish operations, for which a Well Project Logistics Plan is carefully designed, with integrated planning and management of all areas involved.

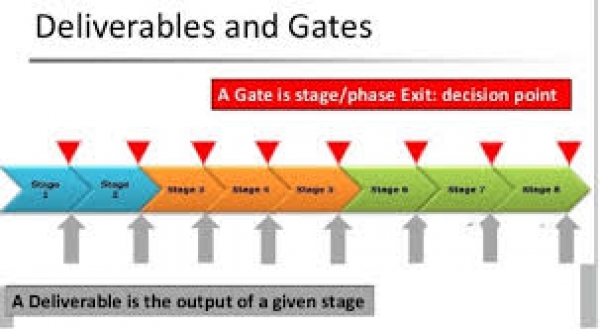

My suggested approach allows for a paradigm shift, merging the concepts of integrated operations and supply chain practices, while applying the Well Delivery Process to improve project performance. The well delivery process execution-flowchart accounts for FEL methodology which provides the means for organizations to develop plans and oversee operations by reviewing the information furnished by project technical teams and setting stage-gates for reviewing project planning, where the management team decides whether the project may proceed to its next stage assuming an tolerable level of risk and uncertainty.

This proposal is based on both available literature, articles and essays presented at international events of the oil and gas industry that deal with projects executed in remote areas, and my professional experience. This proposed methodology shall serve as a contribution to implement best practices and develop governance guidelines & structured project methodologies, focused on logistics support to establish exploratory offshore drilling operations.